Bearing support

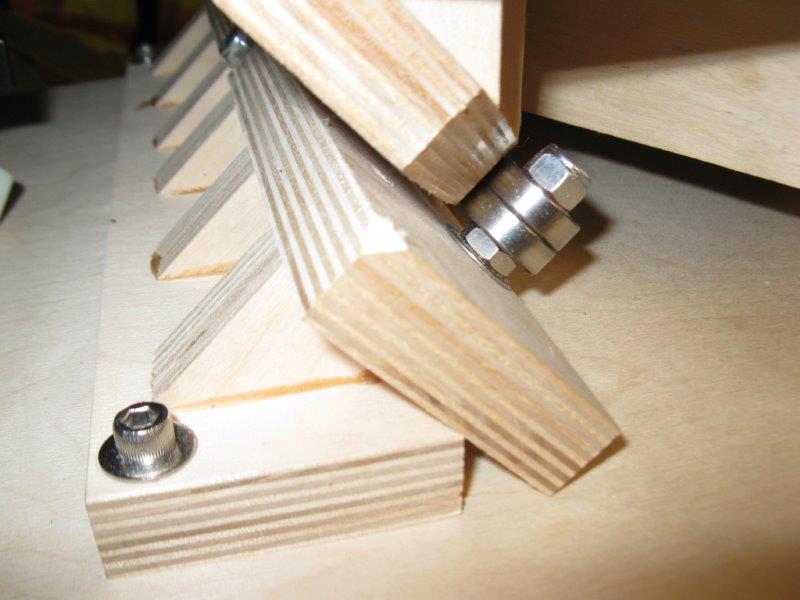

The SkyStopper uses roller blade bearings, mounted rigidly to a holder which then attaches to the base plate with adjustable stainless steel cap screws, into tee nuts on the underside of the base.

All of the wedges used in the construction of a SkyStopper are cut from the same saw setup in one session. The wedges and arcs work together to ensure a pure rotation of the platform.

The arc boards are glued to the rocker plate while held in an adjustable jig to ensure they are parallel and centered. The bearing supports must be positioned parallel to their arcs, and centered on the center line of the base. Key to ensuring proper alignment is the arc bearing support unit.

The arc bearing support is assembled with a special alignment jig, and then positioned on the base with another alignment jig. If you want to finish the base of your SkyStopper the arc bearing supports can be removed and replaced. It's recommended to mark the exact positions as they are factory set, but there's a way to manually align them.

Double bearings on the loaded surfaces are used. Stainless steel bearings are available for extra cost, but not really needed.

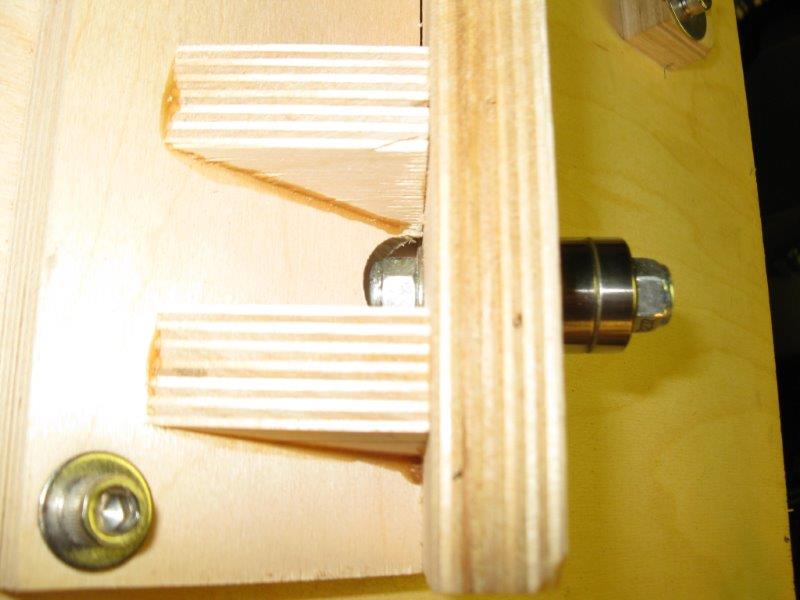

Replacing a bearing is easy. Just hold the nut below the bearings with a thin wrench, and turn the nylock nut to remove it. New bearings just drop into place and the nylock nut can be re-tightened.

The center bearing for each arc rides on a piece of formica securely glued to the face of the arc board.

The forces in play are as follows. For a typical latitude near 45 degrees, the force multiplier is 1.4. For a typical 120 pound Dob, the numbers below are examples. The further south, the less the force multiplier.

Each of the 2 main bearings support about 1/2 of the telescope weight, (56 pounds) after applying the force multiplier. Each of the small arc bearings support about 1/4 of the telescope weight (28 pounds). The center bearing on the small arc supports about 1/2 of the telescope weight, (56 pounds) and the center bearing on the front support gets about 100 percent of the telescope weight. (113 pounds) These forces are rolling lateral forces on the bearing, and are constant in direction. 45 degrees is the worst case. Forces are lower at higher and at lower latitudes.

If the example is repeated for the latitude of 20 degrees, all the forces become lower. In this case, the force multiplier increases the weight to 128 pounds, and the lateral force on the center bearings is reduced to 1/3 of the scope weight. So there would be 43 pounds on the main bearings, and 22 pounds on the small arc bearings, with 25 pounds on the center main bearing and 15 pounds on the center small arc bearing. The threaded rods supporting the bearings are 5/16-24 and are inserted into threaded holes in the wood for better positioning rigidity. They can easily support the forces mentioned. The maximum case is a 200 pound telescope on a platform designed for 60 degree latitude. North of 48 degrees, a second set of center bearings are used to spread the forces.